How fiber measurement drives green manufacturing practices in modern industry

The Role of Optical Fibre Diameter Analyser in Quality Assurance Processes

In today's open market, keeping high-grade optical fibres rests on accurate diameter dimensions. You understand that also small discrepancies can lead to efficiency problems and consumer discontentment. That's where the Optical Fibre Diameter Analyser comes right into play, improving high quality control processes and guaranteeing compliance with rigorous standards. However just how specifically does this modern technology boost item reliability and effectiveness? The solutions may stun you.

Comprehending Optical Fibre Diameter Analyser Technology

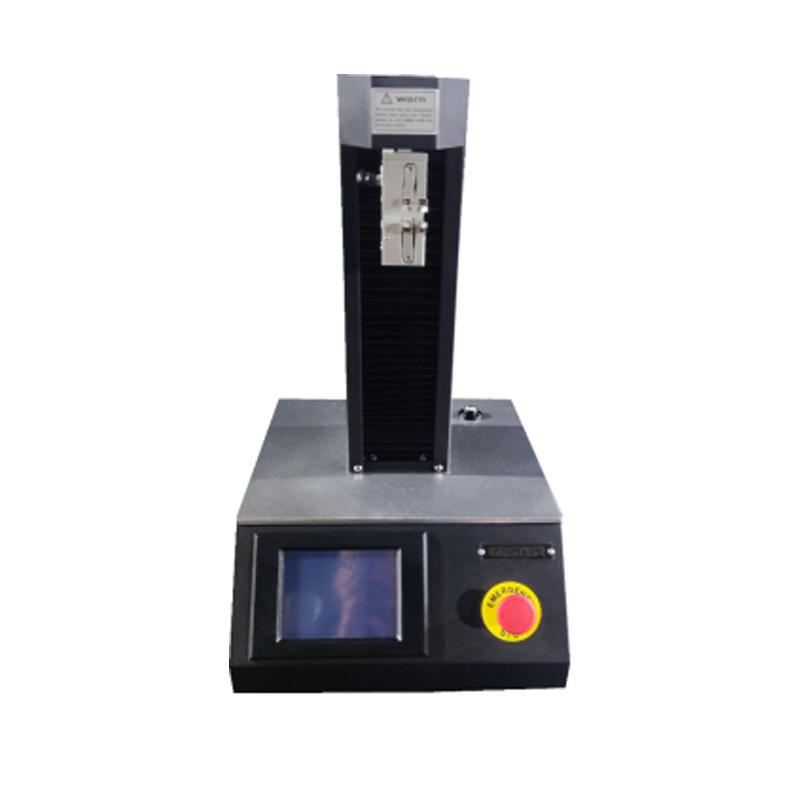

When it concerns making certain the high quality of optical fibres, understanding the innovation behind Optical Fibre Diameter Analysers is crucial. These devices use sophisticated measurement techniques to accurately analyze the size of optical fibers. By using laser-based systems or high-resolution cams, they record real-time data, which enables for exact measurements.You'll locate that lots of analysers incorporate software program that examines the collected data, supplying instant comments on diameter variants. This responses is important for keeping consistent fibre top quality and avoiding problems. The technology additionally includes calibration functions, making certain accuracy over time.Moreover, Optical Fibre Diameter Analysers are developed for fast procedure, making them excellent for high-volume production atmospheres. The convenience of use means you can simplify your quality assurance processes without compromising accuracy. Recognizing these technical aspects encourages you to leverage the analyser efficiently, improving your production effectiveness and item high quality.

Significance of Accurate Diameter Measurement

Accurate size measurement is essential in the production of optical fibers, as also mild variants can lead to considerable efficiency issues. When you're making fibres, you require to assure that their sizes stick to rigorous specs. If the diameter is as well big or as well small, it can influence light transmission, bring about indicate loss or distortion.Using an optical fiber size analyser helps you keep accuracy throughout the production process. With real-time dimensions, you can swiftly determine any type of inconsistencies and make immediate changes. This not only prevents waste however likewise minimizes the threat of pricey rework later on on.Moreover, regular size measurements contribute to harmony in fibre performance, which is important for fulfilling market requirements. By prioritizing exact diameter dimension, you're not simply boosting your production efficiency; you're also ensuring that the end product fulfills the assumptions of your customers.

Impact on Product High Quality and Integrity

Accurate Size Measurements

Accuracy in diameter dimensions is crucial for guaranteeing top notch fiber optics. When you utilize a fiber optics diameter analyser, you can properly determine the diameter of each fiber strand. This precision straight affects the overall performance and reliability of your products. If the diameter is off, it can result in concerns like signal loss or decreased strength, which eventually influences your clients' fulfillment. By consistently determining the size with accuracy, you reduce problems and boost the longevity of your fibers. This not only increases your online reputation yet also lowers expenses connected with returns and rework. In the affordable fiber optics market, ensuring precise diameter dimensions can be the differentiator that sets your items aside from the rest.

Consistency in Production

Consistency in production plays an essential function in figuring out the general top quality and reliability of fiber optics. When you maintain consistent size throughout sets, you're guaranteeing that each fiber carries out as expected, lowering the danger of failings throughout use. By utilizing an Optical Fibre Diameter Analyser, you can closely keep track of and manage this consistency. This tool assists you quickly identify any deviations, enabling you to take corrective action prior to problems rise. Consequently, your final items fulfill rigid market requirements, improving consumer satisfaction. Furthermore, regular production lessens waste and decreases costs, making your procedures much more efficient. Eventually, prioritizing uniformity doesn't just boost your fiber optics; it solidifies your online reputation on the market as a relied on supplier.

Real-time Surveillance and Information Evaluation Capacities

With real-time tracking, you obtain instant information collection that maintains you informed about the optical fiber's diameter. This ability permits constant top quality assessment, guaranteeing that any inconsistencies are caught right away. By leveraging these features, you can boost your quality assurance procedures effectively.

Immediate Data Collection

As you implement the Optical Fibre Diameter Analyser in your quality assurance process, you'll quickly value its immediate information collection capabilities. This device permits you to gather important information on fibre diameter immediately, allowing you to make enlightened decisions instantly. You will not need to await lengthy records or hands-on information access; instead, you'll get real-time updates that keep you in control. With its straightforward user interface, you can quickly track measurements and identify any kind of anomalies promptly. This swift data collection not only boosts your efficiency but likewise advertises much better interaction amongst your group. By leveraging this technology, you'll streamline your processes and guarantee that high quality standards are consistently fulfilled.

Continuous Quality Assessment

While preserving quality standards is essential, the Optical Fibre Diameter Analyser empowers you with constant top Discover More Here quality analysis with real-time tracking and data evaluation. This gadget enables you to track fibre size variations promptly, making sure that any discrepancies from requirements are identified quickly. You can identify fads and patterns in your manufacturing procedure, enabling proactive changes before issues rise. By incorporating this analyser right into your operations, you'll improve your capacity to keep consistent high quality and lower waste. Real-time information supplies insights that educate decision-making, assisting you accomplish peak efficiency. With the Optical Fibre Diameter Analyser, you're not simply reacting to high quality concerns; you're proactively managing them, guaranteeing your items fulfill the highest possible standards consistently.

Conformity With Market Specifications and Laws

Ensuring conformity with industry criteria and laws is necessary for manufacturers of optical fibres, as it directly impacts item top quality and consumer complete satisfaction. By utilizing an Optical Fibre Diameter Analyser, you can properly determine fibre sizes, ensuring they satisfy the specified tolerances established by governing bodies. This assists you stay clear of costly charges and remembers, fostering count on with your clients - optical measurement system.Moreover, sticking to these criteria not just improves your online reputation but likewise boosts your competitive side. Consumers prefer products that conform with well established policies, knowing they're receiving reliable and risk-free materials. Executing extensive quality control procedures helps you stay on top of these requirements.Regular audits and documents of your quality assurance actions will certainly additionally demonstrate your commitment to compliance. By incorporating the Optical Fibre Diameter Analyser into your quality control procedures, you can improve adherence to industry standards and inevitably enhance your total item offerings

Lowering Waste and Improving Effectiveness

Future Trends in Optical Fibre Diameter Evaluation

As improvements in technology remain to form the future of production, optical fiber diameter evaluation is positioned for considerable advancement. You'll find that automated systems incorporating fabricated intelligence are acquiring traction, improving precision and rate in measurements. These systems can swiftly adjust to varying production conditions, permitting real-time tracking and adjustments.Moreover, anticipate to see renovations in data analytics. By leveraging large data, you'll have the ability to analyze fads and anticipate potential high quality issues before they occur. This proactive method lessens waste and maximizes about his efficiency.Additionally, integration with Sector 4.0 innovations will certainly streamline your quality control processes. optical measurement system. Smart sensing units and IoT gadgets will provide seamless interaction in between makers, making certain peak performance.Finally, innovations in products scientific research might bring about brand-new optical fibres with enhanced buildings. This will certainly necessitate a lot more sophisticated size evaluation strategies, driving advancement in the field

Frequently Asked Questions

What Kinds Of Optical Fibres Can the Analyser Action?

The analyser can gauge numerous kinds of optical fibres, consisting of single-mode, multi-mode, and specialized fibres. It assures precise size dimensions, helping you maintain consistent quality throughout different fibre key ins your applications.

How Usually Should the Analyser Be Calibrated?

You need to calibrate the analyser consistently, ideally on a monthly basis or after significant use. This assures exact dimensions and keeps the quality of your optical fibres, stopping possible errors that can impact your results.

Can the Analyser Detect Size Variations in Real-Time?

Yes, the analyser can discover diameter variants in real-time. It consistently checks the fiber's size, giving immediate responses. This capacity aids you ensure consistent top quality and make instant adjustments if any type of disparities develop.

What Is the Cost Variety for Purchasing an Analyser?

The expense range for acquiring an analyser usually differs in between $5,000 and $50,000, relying on features and specs. You'll desire to contemplate your budget and details needs when deciding.

Exactly how Mobile Is the Optical Fibre Diameter Analyser?

The optical fibre diameter analyser is rather mobile, allowing you to easily carry it in between areas. Its small design and lightweight products assure you can take it any place you require for fast and reliable measurements.